The Strong-Rod Anchor Tiedown System for shearwall overturning restraint (ATS) and Strong-Rod Uplift Restraint System for roofs (URS) address many of the design challenges specifically associated with mid-rise buildings that must withstand seismic activity or wind events. These systems are designed to restrain both lateral and uplift loads, while maintaining reasonable costs on material and labor.

Strong-Rod ATS solutions address the many design considerations necessary for ensuring proper performance against shearwall overturning, such as rod elongation, wood shrinkage, construction settling, shrinkage compensating device deflection, incremental loads, cumulative tension loads and anchorage.

Strong-Rod URS solutions focus on effective performance against roof uplift, taking into account factors such as rod elongation, wood shrinkage, rod-run spacing, wood top-plate design (connection to roof framing, reinforcement at splices, bending and rotation restraint) and anchorage.

Cost-saving components in Strong-Rod systems include expanding aluminum take-up devices for rods up to 1 3/4-inch diameter and increased shrinkage capacity, and RTUD5 and RTUD6 ratcheting take-up devices designed for 5/8- and 3/4-inch-diameter threaded rod, respectively. Once the RTUD take-up devices are installed on top of bearing plates, a series of internal threaded wedges enable the device to ratchet down the rod as the wood structure shrinks but engage the rod in the reverse direction when under tensile loading, ensuring continuous engagement and enabling the rod system to perform as designed. Unlike similar products, the RTUD can be attached using nails or screws.

To support designers as they determine the most appropriate solution for their mid-rise project, Simpson Strong-Tie offers:

- A new Strong-Rod Systems Design Guide (F-L-SRS15) that provides designers with critical information about the specific challenges and solutions available to address shearwall overturning restraint and roof uplift restraint. The 68-page guide explains three methods of specification and includes design considerations and checklists. This guide is now available in print or for download.

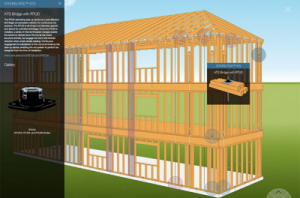

- A new Strong-Rod Systems webpage that features an interactive 3-D graphic of a mid-rise building under construction, showcasing ATS and URS runs in a continuous load path.