“Modern architecture does not mean the use of immature new materials; the main thing is to refine materials in a more human direction.”—Alvar Aalto

Nearly 40 years after his passing, the late Finnish architect and designer Alvar Aalto’s insight into his craft takes on almost prophetic proportions, his words echoing with renewed relevance as the design and construction industry enters an era in which the relationship between materials and human health has become the focus of the green-building movement.

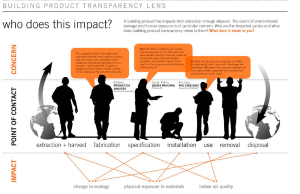

With the launch of the Health Product Declaration (HPD)—a standard format for reporting product content and associated health information for building products and materials—in 2012 and its adoption into LEED v4 as a formal credit under the Materials & Resources (MR) category, material and human health are rapidly encouraging market transformation. Product and furniture manufacturers are responding to increased demand by specifiers to disclose the genetic make-up, so to speak, of their offerings so that the relationship between buildings and the effect they have on the occupants who work, learn, live and heal within them can be more clearly understood and improved.

As reported in retrofit’s September-October 2013 issue, page 68, this evolution toward understanding and ultimately minimizing negative impacts on human health represents the next logical progression in sustainable development as disclosure in product and furniture manufacturing is essential to making that happen. And thanks to the recent formation of the Harmonization Task Group, material ingredient reporting is about to become a much more straightforward, consistent and—most importantly—transparent process.

Optimization through Harmonization

Among the biggest challenges today facing purchasers and specifiers of healthy, sustainable products is knowing how to determine which ones are actually safe for environmental and human health. A myriad of third-party certification programs, such as Cradle to Cradle, EcoLogo, ENERGY STAR, FloorScore, FSC, GREENGUARD, level, SFI and many others, have flooded the market in the past 10 to 20 years, all of which lay claim to a slice of the green-products pie. Unfortunately, these programs do not use a consistent method or standard for evaluating a material’s composition or impacts—the result of which has been confusion in the market and an inability to provide purchasers with an apples-to-apples comparison of green products.

“There are so many different standards out there, how do you know which one to pick?”, muses Breeze Glazer, LEED AP BD+C, sustainable design leader, research knowledge manager and senior associate at Perkins+Will, New York City. “I think it makes a whole lot of sense to get to that single level of standardization for reporting out the chemical composition and health issues related to materials.”

Thankfully, a number of established organizations, including the Cradle to Cradle Products Innovation Institute, Healthy Building Network, Health Product Declaration Collaborative and the Clean Production Action, have set out to do just that by forming the Harmonization Task Group, or HTG. HTG’s members are participating in a collaborative effort to share resources that make it easier for manufacturers to examine and optimize their products for human and environmental health. Among HTG’s goals are to improve product ingredient reporting by providing access to reliable chemical hazard assessments and identify safer alternatives to manufacturers seeking to create healthier, more sustainable materials and furnishings.